When a nonconformity occurs within a system, process, or product, the initial reaction individuals often have is to immediately correct the issue at hand. Although it is critical to ensure the nonconformity is addressed in an appropriate manner, it is also important to identify the potential causes for why the nonconformity occurred to begin with. By understanding potential causes as personnel working within a quality system, we can see what attributes we need to carefully observe and address when resolving the nonconformity to ensure it does not reoccur.

When a nonconformity occurs within a system, process, or product, the initial reaction individuals often have is to immediately correct the issue at hand. Although it is critical to ensure the nonconformity is addressed in an appropriate manner, it is also important to identify the potential causes for why the nonconformity occurred to begin with. By understanding potential causes as personnel working within a quality system, we can see what attributes we need to carefully observe and address when resolving the nonconformity to ensure it does not reoccur.

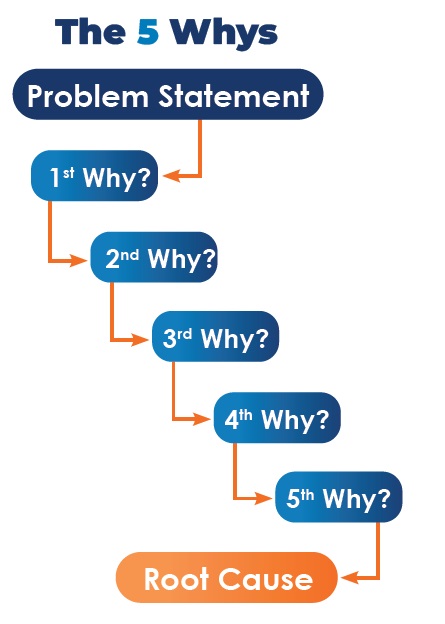

One great aspect of ISO/IEC 17025 is that the standard allows organizations to design their quality system using tools that will help them best meet the requirements (i.e., sections 7.10 and 8.7). Properly understanding the cause for why a nonconformity occurred allows us to understand the risks associated with previous work, whether something may reoccur, and how a problem lives in the system. One method commonly used to evaluate potential causes is known as the “5 Whys” method.

The 5 Whys is a straightforward method of analysis which uses a problem statement and follow up questions to dig past the surface of an issue and understand the underlying causes. To show how this process works and allow for additional understanding of the issue and its potential causes, we will walk through how the 5 Whys work in a real-world scenario. In this scenario, we are a chemical testing laboratory named ABC Laboratories, which is accredited to ISO/IEC 17025. During our most recent assessment, our assessor found that our most recent management review did not include customer and personnel feedback.

Per ISO/IEC 17025: 2017, the non-conformance would be the lack of meeting Section 8.9.2.i of the standard, which requires that the management review shall include information related to customer and personnel feedback. Using this nonconformity to walk through the 5 Whys method, we’d start by re-writing it as the initial problem statement.

PROBLEM STATEMENT: No evidence was available during the recent assessment of ABC Laboratories that showed that customer and personnel feedback were addressed during the most recent management review.

With the 5 Whys technique, we simply take the problem statement and ask ourselves why. For our real-world scenario, the answer may be as follows:

PROBLEM STATEMENT: No evidence was available during the recent assessment of ABC Laboratories that showed that customer and personnel feedback were addressed during the most recent management review.

WHY: Why was there no evidence showing customer and personnel feedback during the most recent management review?

ANSWER: Customer and personnel feedback were not addressed in the most recent management review because the template used did not have a line item to add them as an input per

ISO/IEC 17025: 2017 8.9.2.i.

In this scenario, the answer is determined by discussing the non-conformity with other staff working together on the resolution. Moving forward, we take the answer provided and again, ask why. We repeat this process enough times so that we have asked why 5 times. By asking why 5 times, we know we have dug deep enough to have a better understanding of the problem and what might have caused it to occur. For our scenario, the entire process could be expressed as the following:

In this scenario, the answer is determined by discussing the non-conformity with other staff working together on the resolution. Moving forward, we take the answer provided and again, ask why. We repeat this process enough times so that we have asked why 5 times. By asking why 5 times, we know we have dug deep enough to have a better understanding of the problem and what might have caused it to occur. For our scenario, the entire process could be expressed as the following:

PROBLEM STATEMENT: No evidence was available during the recent assessment of ABC Laboratories that showed that customer and personnel feedback were addressed during the most recent management review.

WHY 1: Why was there no evidence showing customer and personnel feedback during the most recent management review?

ANSWER: Customer and personnel feedback were not addressed in the most recent management review because the template used did not have a line item to add them as an input per ISO/IEC 17025: 2017 8.9.2.i.

WHY 2: Why was there no line item on the management review template for customer and personnel feedback?

ANSWER: It was missed when we updated the management review template from ISO/IEC 17025: 2005 to ISO/IEC 17025: 2017.

WHY 3: Why was the line item missed when revising the management review template?

ANSWER: It was missed because we updated the template right before an assessment by our accreditation body, and we were in a rush.

WHY 4: Why were you in a rush to update the template before an assessment?

ANSWER: We were in a rush because there was no time earlier in the year to update the template.

WHY 5: Why was there no time earlier in the year to update the template?

ANSWER: There was no time earlier in the year to update the template because our organization recently changed quality managers and were integrating them into the system.

As you can see from our example, we learn a lot about our system and the potential reasons for why a nonconformity might occur with this technique. Keep in mind that when performing the 5 Whys, you do not necessarily have to ask why only 5 times. It could be as little as 3 times, or even 7 or more. The number of times depends on how many are necessary for your organization to feel that a substantial level of depth has been established. We want to make sure we set ourselves up for success; having an appropriate grasp of how an issue occurs lets us utilize our tools and time better when trying to determine what needs to be done to resolve the issue.

The 5 Whys is one example of different ways organizations can evaluate the causes of a non-conformity. If one tool feels more appropriate for the scenario your organization is working through, then don’t feel pressured to utilize one stock method. For simple issues and non-statistical issues, something like the 5 Whys can help keep your analysis simple and easy to digest. Remember, as organizations we understand how our system functions, and as such, we can use the tools best suited for our organization to meet the requirements of ISO/IEC 17025.

By Jenna Schoettker, A2LA Senior Accreditation Specialist