One of the key differences between materials testing and inspection is the idea that inspection relies more heavily on the competency and qualifications of the technical personnel while materials testing results rely heavily on the metrological traceability of the equipment being used. ISO/IEC 17025 accounts for those traceability requirements and puts a greater emphasis on ensuring that equipment is handled properly, checked periodically, and kept in good working order. In the inspection world, the equipment is used to assist the inspector in making a judgement call for the inspection; however, the traceability of that equipment may not be as critical to the overall result of the inspection. The credibility of inspection results hinges primarily on the inspector’s competency, qualifications, and overall impartiality and conduct.

The ISO/IEC 17020 standard can apply to many different industries including building inspections, cybersecurity, forensics, pipelines, amusement rides, and cargo inspections. The bulk of these inspections use different methods of visual inspection to verify that a product meets a specific set of requirements. Typically, there is not a testing value assigned to these inspection results; instead, the inspector issues a pass/fail judgement and provides an overall report with any nonconformities. One of the challenges that these inspectors face is that without specific values given from traceable equipment or other concrete information, the bulk of their decision rests on their expertise. Inspection agencies that oversee those inspectors also have the challenge of making sure that each of their inspectors performs inspections consistently and competently.

Monitoring Requirements

ISO/IEC 17020 also contains specific requirements for monitoring. ISO/IEC 17020:2012 sections 6.1.8 and 6.1.9 state, “Personnel familiar with the inspection methods and procedures shall monitor all inspectors and other personnel involved in inspection activities for satisfactory performance. Results of monitoring shall be used as a means of identifying training needs (see 6.1.7). Each inspector shall be observed on-site, unless there is sufficient supporting evidence that the inspector is continuing to perform competently.” This is critical to ensure that all inspectors are performing the inspection methods consistently. As an organization, it would not be helpful if one inspector representing you would get one result versus another getting a completely different result when they are following the same process. When determining the frequency of monitoring inspectors, the following should be considered: the risk and complexity of the inspections, the historical performance and experience of the inspector, and any technical or procedural changes to the inspections. Monitoring can also be used as a tool to identify potential training needs or additional improvements to the management system.

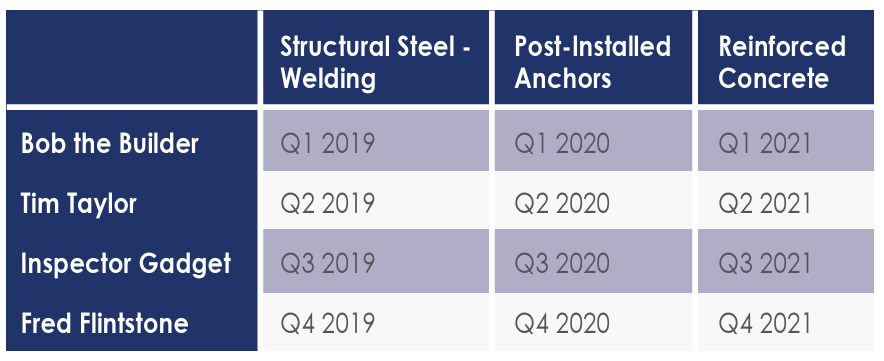

According to ILAC P15 Application of ISO/IEC 17020:2012 for the Accreditation of Inspection Bodies, “to be considered sufficient, the evidence that the inspector is continuing to perform competently should be substantiated by a combination of information such as; satisfactory performance of examinations and determinations, positive outcome of report reviews, interviews, simulated inspections and other performance assessments (see note to clause 6.1.8), positive outcome of separate evaluations to confirm the outcome of the inspections (this may be possible and appropriate in the case of e.g. the inspection of construction documentation), positive outcome of mentoring and training, absence of legitimate appeals or complaints, and satisfactory results of witnessing by a competent body, e.g. a certification body for persons.” These are all examples of ways that monitoring is conducted; however, the expectation is that records or evidence of this monitoring is maintained. Some accreditation bodies or other regulatory agencies may require a documented plan for how an organization intends to monitor each inspector. For example, A2LA requires that inspection bodies have a documented plan of how they intend to witness all inspectors performing all major types of inspections over a four-year period. The inspection agency can still decide how often specific inspections or inspectors are witnessed, and the plan can always be adjusted, but at a minimum, each type of inspection needs to be monitored for each qualified inspector.

Example: “The company monitors inspectors periodically in the field but not less than once every three years for each field of inspection.”

Sources: ISO/IEC 17020: Conformity assessment – Requirements for the operation of various types of bodies performing inspections ILAC P15 Application of ISO/IEC 17020:2012 for the Accreditation of Inspection Bodies